Introduction

In the modern era of dentistry esthetics plays a pivotal role in the success of restorations. The basic aim of restorative dentistry is to replace the lost tooth structure and restore the tooth form, function and esthetics, while maintain the physiological integrity in harmonious relationship with adjacent soft and hard tissue all of which should enhance the general health and welfare of patient.1

Surface roughness due to improper finishing and polishing of dental restorations can results in excessive plaque accumulation, gingival irritation, increased surface staining and poor esthetics of restored teeth that could potentially lead to demineralization of enamel possible recurrent caries and periodontal problems. Furthermore, patient’s consciousness of restorations with possible irritation to tongue, lips and cheeks is a matter of concern. Therefore, smoothness of restorations is of utmost important for its success.2

Finishing and polishing techniques employed varies with the type of restorative material such as composite. Tooth colored restorative materials require adequate finishing and polishing for its longevity. Among the wide variety of finishing and polishing devices that are available in the market such as silicon carbide coated or aluminum oxide coated abrasive discs, impregnated rubber as silicon discs, and wheels, multifluted tungsten carbide burs and hard bonded surface coated ceramic diamond rotary instruments are most commonly used to finish and polish composite restorations.3

Mechanism of finishing and polishing

The mechanisms involved in mechanical finishing and polishing using abrasive particles are part of tribiology, the discipline associated with material science, physics, chemistry and surface contact engineering. A description of a tribiological system consists of a set of experimental parameters (eg, applied load, velocity, and duration of motion) and the system structure (eg, the two bodies in contact, the interfacial media, and the surrounding media).4 These are two-body abrasion and three-body abrasion. In a two-body mode, the bound abrasive particle is solidly fixed to the substrate. In a three-body abrasive mode, free (or loose) particles form slurry between the specimen surface to be polished and a flat polishing substrate. Most dental finishing and polishing devices operate in the two body mode. Three-body abrasive wear occurs when loose particles move in the interface between the specimen surface and the polishing application device.5

Factors affecting finishing and polishing of composites

Dental composites are among the most difficult types of materials to predictably finish and polish to a high luster because they contain a relatively soft resin matrix and hard filler particles in their structures. In addition, the final finish of a composite restoration depends on the fillers and resin matrix, the preparation design, curing effectiveness, and postcuring time required for the material to achieve its final properties. For some composite materials, a delay of 10 minutes or more is recommended after curing to allow complete polymerization to occur. Curing lights for polymerization such as halogen lamps must produce a minimal light output of 475 nm/mm2 for most photo initiated composites.6

Chemically cured composites must be properly placed in the prepared tooth within the working time of the materials. Exposed filler particles create peaks and valleys that prevent the surface from acquiring a high luster.6

Steps in finishing and polishing of composites

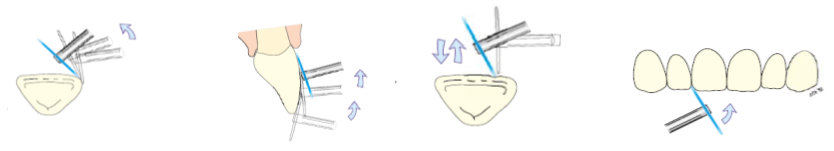

During each stage of finishing and polishing, the operator should proceed in one direction only. Then, after the use of the next abrasive in the sequence, polishing should continue in a direction perpendicular to the previous one. This process ensures that scratches become more visible and that the effectiveness of scratch removal can be assessed more rapidly. The operator can choose to use one system from start to finish (such as abrasive-coated or flexible abrasive-impregnated rubber discs) or combine different systems based on preference and the location of the restoration (such as sandpaper for anterior or a brush for posterior sites).6

Instruments used in stepwise finishing and polishing of composites

Gross contouring- burs, diamonds.

Finishing-discs, cones, wheels, cups, rubber points.

Polishing-bristles, cups, cones.

Fine diamonds are ideal for gross contouring. Micron diamonds are designed for use at slow speeds and with copious amounts of water; however, most practitioners use them at near stall-out high speed. The finish is slightly less smooth than the finish achieved with flexible discs. Thirty fluted burs effectively finish submicron composites.7 Studies show that these diamonds do not damage the resin matrices and margins as much as do some finishing burs.

Forty-fluted burs can be used to trim excess composite resin from under gingival tissues because the burs do not cut tissue and they leave a smooth burnished surface.

Discs and strips, unlike diamonds, are typically measured by grit rather than by micron particle size. Grit is determined by mesh size during manufacture; a disc with a grit of 200 would include a mixture of particles, all measuring 74 μm or less.

Rubber wheels, cups, and points

Polishing cups and wheels yield smooth finishes. They come in a variety of shapes, sizes, and grits. Some of the available rubber wheels, cups, points in market are Centrix polishing cups, shofu polishing cups & wheels, Vivadent polishing cups and wheels and Enhance polishing cups which used for gross and final finishing of ccomposites.

Metal strips

Metal strips cut almost all tooth and restorative materials evenly. They are superior to plastic strips in almost every respect. They are excellent for gross interproximal reduction, particularly as a first step in interproximal finishing,there are wide variety of metal strips are available in market with different grit size from 15 μm to 45 μm e.x Brasseler Diammond strips, Compo- strips by premier and GC metal strips.8

Plastic strips

Flexistrips (Cosmedent) are available in two grits, one for finishing and one for polishing. The strips provide a smooth surface on microfilled composites and are tear resistant.

Moyco Plastic Strips are thick, color-coded strips. They cut more slowly and are less useful for gross reduction.

Sof-Lex Strips (3M) are excellent for final finishing of proximal areas and are understandably popular among dentists. They have an uncoated area in the center of the strip for easy initial placement. They come in two widths and two pairs of grits, one for finishing and one for polishing. Use both strips for optimal results.

Vivadent Strips are available in coarse and medium aluminum oxide. Vivadent’s fine strip is coated with tin oxide and is excellent for polishing when no reduction is desired.8

Technique of finishing and polishing

Hand instruments

Hand instruments include Bard Parker blades and tungsten carbide carvers. A standard No. 12 or No. 15 Bard Parker blade can remove excess restorative material interproximally. Carbide composite carvers, such as those sold by Brasseler and GC America, are available in several shapes, trim a micro filled composite with ease, and hold their edge well.

Creating texture

Creating a textured surface requires polishing to the ideal contour and leaving a slight extra thickness over the area to be textured. Then, with a micron diamond or small disc, indentations of the desired texture are carefully and slowly cut. The tip of the instrument is in constant motion. Generally, horizontal indentations that are straight or broken are made in the gingival third (ie, lift the instrument on and off of the surface), and vertical indentations are made in the incisal two-thirds.

• Step -1 Micron diamonds (40 to 60 μm) are used for bulk reduction on surfaces unreachable with discs. Micron diamonds used at slow or stall-out speeds with copious amounts of water provide a smooth surface with minimal resin damage.

• Step 2- Flexible discs and strips (eg, Sof-Lex, 3M) give an excellent finish. The coarse discs are used with water and with a very light touch. Because heat and friction weaken the composite and enamel–resin interface, discs should be moved constantly to prevent heat and flat spots. Flexible discs cut composite more rapidly than enamel and can easily ditch composite. Discs with more rigid backing are used to polish the margins of materials with different cutting rates. Special discs are made for this purpose (eg, XT, 3M; and several by Cosmedent).

• Step 3-polishing, Polishing pastes should be used on micron and submicron macrofilled composites. Special polishing pastes with a fine polishing grit are designed forsubmicron composites. On large-particle composites, the pastes have a tendency to selectively remove more of the soft matrix resin than the hard filler.

Use of flour of pumice, tin oxide, and rubber wheels should be avoided because they increase the roughness of large-particle composites

Acquired: inherent polish ratio

There are two kinds of polish: acquired and inherent. The acquired polish is the surface placed by the operator. The inherent polish is the surface the material naturally reverts through mastication and erosion. This surface is largely determined by the size and solubility of the dispersed phases of the material used (eg, fillers, fibers, etc).

If the acquired-to-inherent polish ratio (A:I ratio) is 1:1, the surface texture will never change.

Because almost all restoratives are heterogeneous materials, they become rougher over time. Microfills have a low A:I ratio since both filler and matrix are similar. Large-particle macrofills have a large A:I ratio, because their surface becomes more rough over time

Wet or dry finishing

Dry finishing is very harmful to most restoratives. The heat and friction generated can open dentin margins, particularly dentin composite margins. Dry finishing should be reserved for microfilled composite resins because they contain only resin fillers, which melt and produce an artificial smear layer of resin that enhances the surface gloss. Wet finishing, reduces heat and friction, and thus, reduces surface damage to the body and margins of the restoration.

Conclusion

The finishing and polishing is one of the most important steps in restorative treatments as it increases the longevity of the restoration. Composite resin restorations if finished and polished in proper sequence can last for long time and provide satisfaction to the patient. eEch and every step starting from gross reduction to fine finishing and polishing need to be done in correct sequence to achieve optimal results.